Deep-UV LEDs: Start-up seeks success with a fab-lite focus

A Norwegian start-up looks to prosper in the deep-UV LED market with reliable, packaged emitters.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

The razor thin margins facing makers of visible GaN-based LEDs has ensured that this market is anything but a happy hunting ground for start-ups. But fledgling firms with interest in this area do have the tantalising prospect of significant, lucrative success, if they can produce variants that provide emission in the deep UV.

That’s the market being pursued by fab-lite firm CrayoNano, which has already raised €30 million and has the opportunity access on another €5 million, if necessary. Based in Trondheim, Norway, this spin-out of the Norwegian Technology University has established product design and processing facilities at its head-quarters and in Taiwan, and developed a production process for making high-performance UVC LEDs that can be undertaken in any high-volume fab that makes GaN-based LEDs.

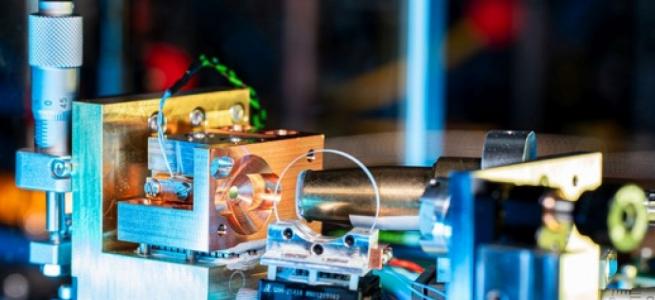

The company’s first product line, the CrayoLED, draws on fundamental research and IP conducted into graphene and GaN-based nanowires. While details of this technology are currently under wraps – more will be said in 2023, via an exclusive feature in Compound Semiconductor, so watch this space – CrayoNano is willing to discuss the performance of its deep-UV LEDs, its fab-lite strategy, and the market opportunities for its packaged emitter.

According to Michael Peil, CrayoNano’s Chief Revenue Officer, although the company’s debut product, which has been developed in cooperation with key customers, doesn’t break any records, it is a strong allrounder with an impressive performance on many fronts.

The company’s debut product, the H-Series (CLH-N3S) LED, emits at 275 nm. Targeting water purification, but also suitable for air and water purification, it has an output power of 80 mW. That’s towards the upper end of the range for commercial high-power UV LEDs on the market – they span around 40 mW to 100 mW.

“Some products have a higher output power but much less lifetime,” points out Peil, who adds that to ensure customer confidence in the lifetime numbers that CrayoNano quotes, it uses a third party with an accredited measurement lab to provide this crucial piece of information. There are promising signs from the initial data that the lifetime, based on the time it takes for the output to fall from its initial value by 30 percent, is typically more than 10,000 hours. That’s sufficiently long to enable success in the marketplace.

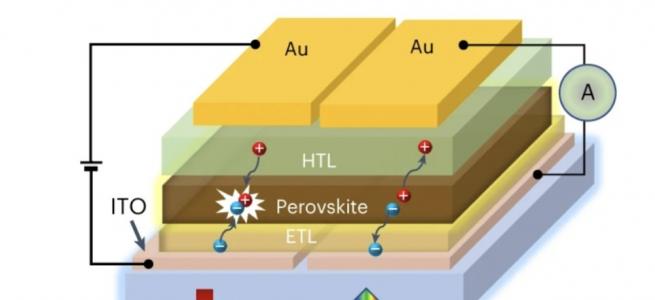

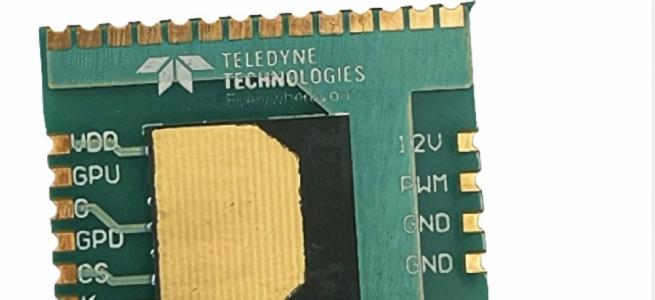

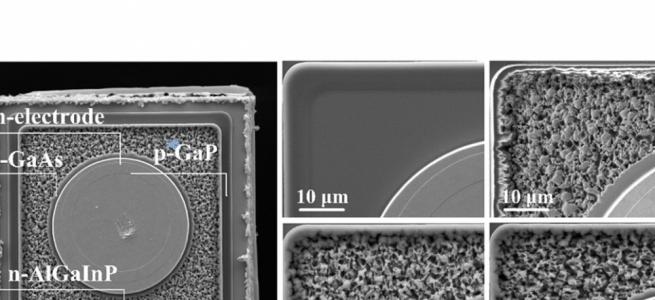

CrayoNano has carefully considered the processing and production that it employs for its packaged UVC chip. “You need to have a high-transparency, endurable packaging technology,” argues Peil. “You can go cheap, but that doesn’t serve the purpose of having a long-life requirement.”

The packaged CrayoLED H-Series UVC LED features a high-thermal-conductivity ceramic to minimise the junction temperature, and optical materials that combine minimal degradation with the ability to direct the emitted light at its intended destination.

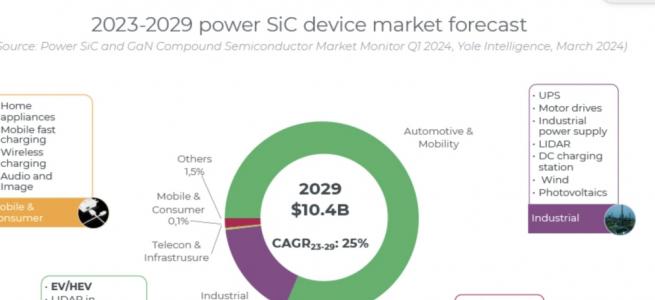

Peil claims that many of the suppliers of UVC LEDs struggle to scale to the high volumes required to unleash a multi-billion-dollar market for this class of device. “[Deep-UV LEDs] need to be produced in hundreds of millions, if not billions of pieces.”

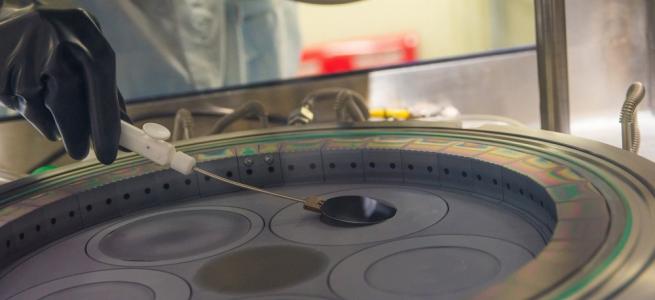

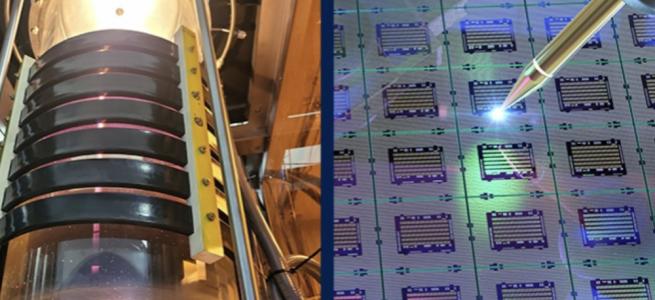

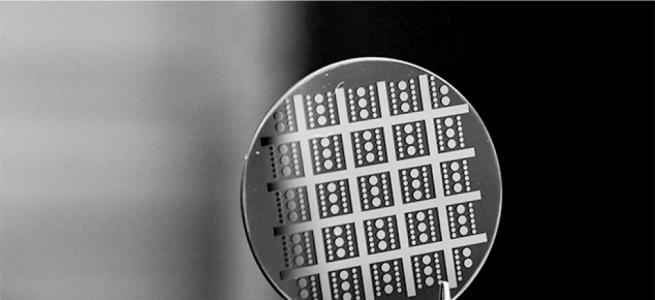

The company’s fab-lite strategy can deliver these volumes. The CrayoNano fab in Taiwan is capable of ramping production to tens of millions of chips – and once that capacity can no longer meet orders, additional production will be provided by several scaling partners, such as SemiLEDs, thanks to the compatibility of the company’s approach with blue-chip MOCVD technology.

“That gives us the possibility to keep cap-ex requirement low, and to diversify the technology,” comments Peil, who reveals that CrayoNano’s long-term ambitions in the semiconductor industry are not limited to LEDs.

By sharing the technology used to manufacture blue GaN-based LEDs,

CrayoNano can ramp to very high volumes with scaling partners.

Covid’s legacy

A capability to kill the Covid-19 virus fuelled tremendous interest in the deep-UV LED during the height of the pandemic, and spurred rocketing sales.

“Covid was a trigger, not only indicating the need for new technology, but also the requirements for standardisation, to make this a good solution for health applications,” remarks Peil.

While we may be transitioning to a world where we live with Covid, new pandemics could emerge, where deep-UV LEDs could have a role to play, including those associated with livestock.

Peil sees the water purification market as an opportunity for fast growth in UVC LED sales. While mercury lamps have a higher efficiency than UVC LEDs – it’s typically 15 percent, rather than up to 5 percent – their bulkiness hampers incorporation in systems for purifying tap water at its point of use. With UVC LEDs delivering high energy densities, emission can be efficiently directed to where it’s needed to provide disinfection, leading to a higher efficiency at the system level.

Local purification of tap water with a deep-UV LED is very attractive, argues Peil. “If we can avoid chlorine utilisation, the taste is better. For example, you will see application in soft drinks mixers at home.”

There’s also the opportunity for grey water re-use. This is already being implemented in Japan, a nation with much resource awareness.

Another resource, currently at the forefront of the minds of many, is energy. Traditionally, thermal processes are used for disinfection, but the high electricity bills now being faced in many countries could drive a switch to deep-UV LEDs.

This is but another example of the many market opportunities for CrayoNano, which will grow shipments of deep-UV LEDs with a fab-lite model that has no constraints over capacity.